18/05/2023

NOx Spot Check – Eurotron RASI Series, Flue Gas and Emissions Analyzers

18/05/2023

NOx Spot Check – Eurotron RASI Series, Flue Gas and Emissions Analyzers

Reference is made to NOx spot check; a periodic test for assessing catalyst NOx reduction efficiency, required by IMO regulations MEPC.291(71)// 3.2.8.2.3*.

NOX spot checking is required by IMO regulations on an annual basis in order to ensure compliance with the Tier III NOX emissions limit and is also needed after installation.

Eurotron Instruments UK ltd, can provide the largest selection of emissions and combustion gas analyzers.

The RASI 800 is MCERTS certified to HEM’s ( Handheld Emissions Monitoring System) and the RASI700 is TUV approved to EN 50379-2.

RASI 700 – Flue gas and emissions analyzer

The RASI700 is a true 8-gas hand held emissions and industrial flue gas analyzer which can be configured to your specific application.

It is the ultimate tool for tuning and servicing industrial boilers and gas and diesel engines.

![]()

![]()

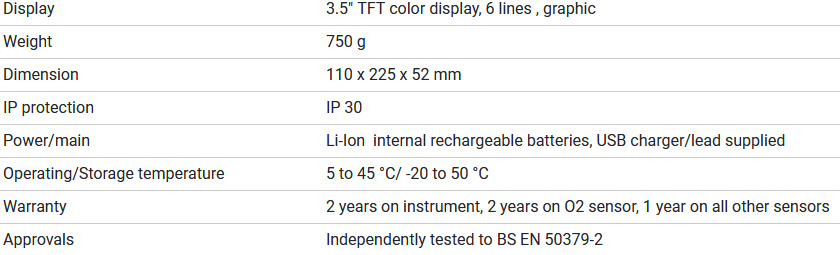

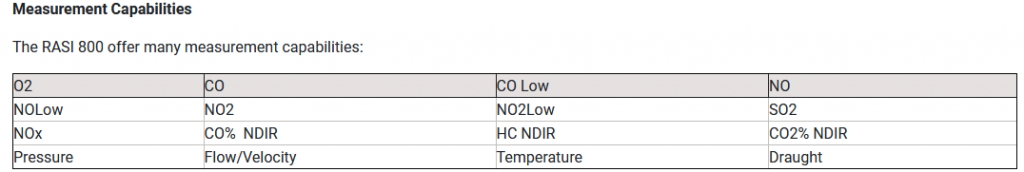

RASI 800 – Portable Emissions and Exhaust Gas Analyzer, MCERTS certified.

The RASI800 is a portable Emissions and flue(exhaust) gas analyzer that meets the MCERTS performance standards for Portable Emissions Monitoring Systems.

The RASI800 portable emissions and exhaust gas analyzer is made up of two separate units, the RCU which control all the function of the analyzer and displays the measurement values and the Analyzer Base which contain all sensors and the gas conditioner system.

*MEPC.291(71) “2017 GUIDELINES ADDRESSING ADDITIONAL ASPECTS OF THE NOX TECHNICAL CODE 2008 WITH REGARD TO PARTICULAR REQUIREMENTS RELATED TO MARINE DIESEL ENGINES FITTED WITH SELECTIVE CATALYTIC REDUCTION (SCR) SYSTEMS”

3.2.8.2.3 guidance on how to assess catalyst NOX reduction efficiency based on periodical spot checks or monitoring as specified by the applicant, if applicable; records are to be kept for inspection during annual, intermediate and renewal surveys. The frequency of periodical spot checks is to be defined by the applicant considering the expected deterioration of the catalyst. The frequency for spot-checks should be at least after installation and once every 12 months.

Σχετικά Νέα & Άρθρα