26/04/2022

On Line Robotic Tank Inspection & Tank Cleaning Management

26/04/2022

On Line Robotic Tank Inspection & Tank Cleaning Management

It is our great pleasure to present below informative material for our recent collaboration with Flow Technology International.

Flow Technology International has developed advanced Services with Remotely Operated Vehicles’ (ROV) Tools for internal tank inspection that can be used while the tank is in operation (online & in service).

The knowledge gained from the in-service inspection can also be used for better maintenance planning and better preparation for a forthcoming shutdown.

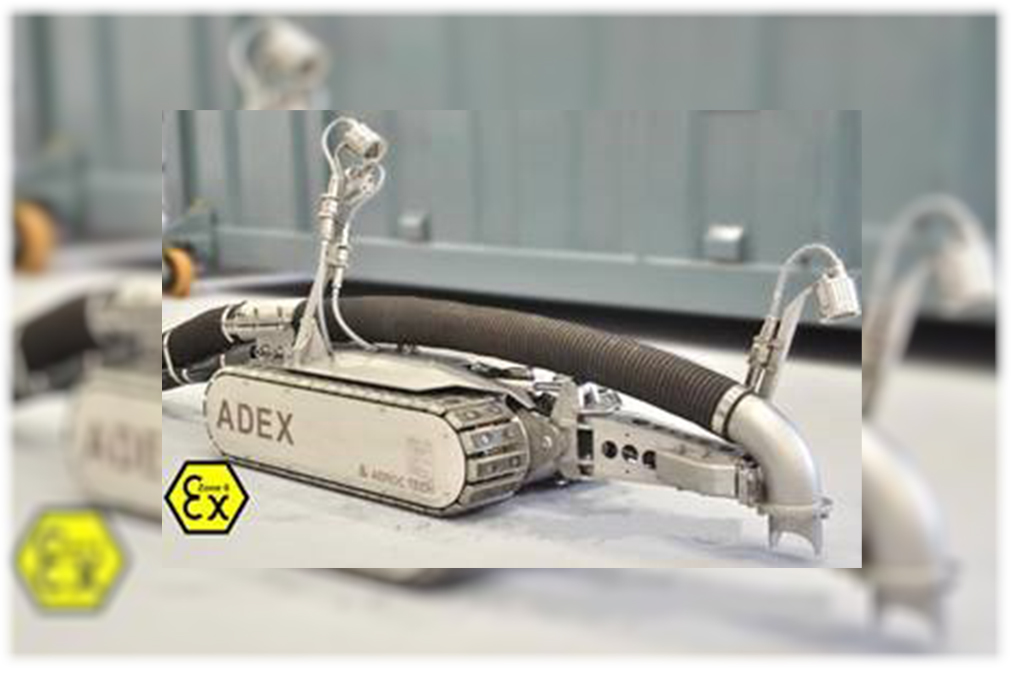

These robotic crawler devices are designed for total immersion in liquids and have been successful in providing ultrasonic thickness information on tank bottoms in clear finished product storage such as gasoline, naphtha, jet fuel, No. 4 and No. 6 fuel oils, condensate, water and crude oil.

Flow Technology International has completed major projects by Online Robotic Tank Inspection and Desludging; a reference list can be provided upon request.

Desludging and Waste Management -Comprehensive in-service inspection

• Advanced Robotic Tank Floor inspection

• Tank Shell and Roof

• Annular Plate and Floor Screening

• Associated Piping

• Tank Management and Maintenance Solutions

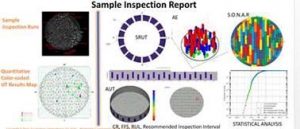

In-Service Inspections Options

• Screening by Acoustic Emission (AE) provides 100% coverage of the tank floor

• Screening of Annular Plate with SRUT

• In-service robotic inspection is performed with sampling coverage

• Density of coverage is guided by AE and SRUT results as necessary

• Sampling coverage is defined to ensure reliable information on the floor minimum thickness

• Advanced statistical methods are used to assess the results

• Calculating AST Remaining Useful Floor Life

Robotic cleaning by Flow Technology International

• The robotic system can use a variety of pumps to pump sludge and sediment into awaiting containers for disposal

• Depending on the sediment level, inspection can occur during cleaning, eliminating the equipment needed for an out-of-service cleaning

• In-service robotics reduce manpower and equipment requirements and eliminate time out of service

• Minimize Confined Space Entry of Personnel

• Minimize Shut Down Time of AST

All the aforementioned Robotic Services are compliant with API 653.

Σχετικά Νέα & Άρθρα