KC Ltd., a world-renowned Korean manufacturer of corrosion protection and anti-fouling systems, offers a high quality solution for maximizing the protection of your assets.

Being in the market for 40 years, they maintain an impressive reference list for all vessel types with innovative products and services.

TECHNAVA SA, the official representative of KC in the Greek market, can assist you on any technical and commercial request for ICCP, M.G.P.S, Shaft Earthing Device and Chlorination System providing best economical offers and technical solutions.

Main Products of KC Ltd.:

Impressed Current Cathodic Protection (ICCP) Systems for any type of vessel:

- Proven reliability and effectiveness due to an advanced systems’ configuration.

- The hull mounted anodes on Titanium and the reference cells are connected to an automatic control panel which produces powerful external current to suppress the natural electro – chemical activity on the wetted surface of the hull.

- Constantly monitor the electrical potential of the seawater/hull interface and efficiently adjust the protective current to the anodes.

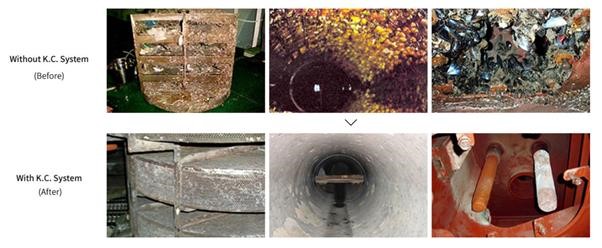

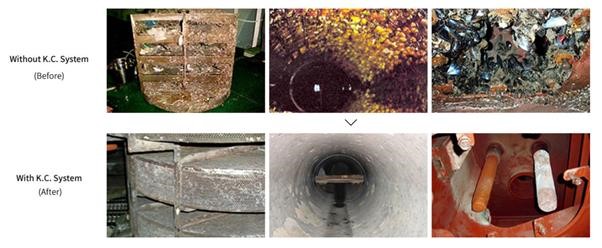

Anti-Fouling System (M.G.P.S – Marine Growth Preventing System):

- Provides continuous anti-fouling protection to the seawater pipes of the ships and all related machinery equipment i.e. valves, condensers, A/C and refrigeration units, firefighting equipment etc.

- The dilution of aluminum/ ferrous anodes produces ions that create an anticorrosive layer on the internal surface of the seawater pipes, protecting them from marine growth and eventually, corrosion effects.

- Ensures the extended lifetime of the seawater pipes.

- Easy to be installed by vessel’s crew, with minimum requirements for maintenance.

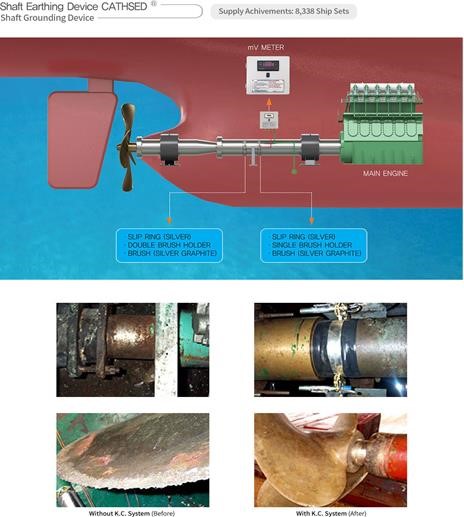

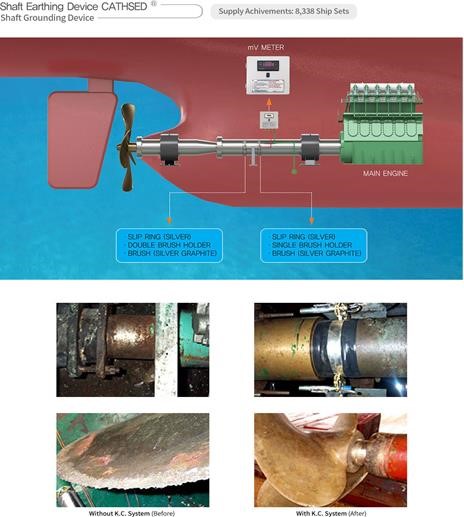

Shaft Earthing (Grounding) Device:

- Ensure low conductivity that maintain max. contact resistance of no greater than 0.001 ohms for a water filled bearing or 0.01 ohms for an oil filled bearing.

- Device comprised of silver graphite brushes mounted on balanced brash holders, running on a copper slip ring with a solid silver inlay track.

Sacrificial Anodes:

- Cathodic protection through galvanic anode system instead of impressed current system.

- Weld-on type and Bolt-on type Anodes for wide installation range.

- Aluminum Anode and Zinc Anode.

- Designed for Ballast tank, Hull, Condenser, Cooler.

Chlorination System:

- Chlorine Generator, equipped with safety features and designed for constant unattended operation.

- Eliminates tidal or temperature induced variance.

- Installation requirements are limited to adequate amount of seawater, electrical power and space.

- The equipment has no moving parts and require little or no maintenance.

- Renewal of Ti anodes is periodically required and can be performed with minimum down time.

Worldwide Service Network:

Certified engineers offer top quality service as follows:

- Engineering and Designing of ICCP systems, Antifouling Systems, Chlorination System Ferrous Ion Generator and Shaft Earthing Device.

- Survey, Supervision and Commissioning of Installation.

- Monthly reporting and monitoring of systems’ performance from KC’s experts.