GABADI LNG

Highly specialized engineering at your disposal.

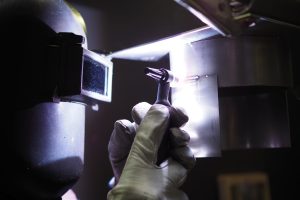

Energy moves the world, and they have been moved by energy. And more particularly, we have experience in all related to LNG type storage systems.

They are the first company, apart from shipyards, which has signed a Technical Service Agreement (TSA) to maintain and refit all type of GTT membrane containment systems, both Mark and NO.

They are the first and only company, apart from shipyards, which has a Technical Assistance and License Agreement (TALA) to mount NO and Mark membrane systems according to GTT requirements.

In 2014, it became the outfitter which performed more repair works of tanks with membrane technology worldwide. Such works were carried out in Europe, Qatar, Dubai, Singapore and Malaysia.

GABADI SL

Founded in 1989 and with identity signs base on quality and service to client, we have grown in a structural way by means of coordinated development of a human team and of technical and economic means.

Our facilities have an extensión of 8.000 sq.m. dedicated completely to development of projects for the naval industry

Gabadi SL is seen like a leading and innovating company in development, production and installation of naval outfitting projets.

Design and engineering

Gabadi S.L. has a technical and human team specialized in Project development of great importance for the naval industry.

Our team of engineers has great experience in naval outfitting and work with specialized software, and the lastest technology:

- 3D design Siemens NX

- FORAN for development of ship structures.

- Finite element calculation by means of Siemens NX NASTRAN.

Production

Gabadi has its own workshops which guarantee our clients an “ad-hoc” service assuring delivery dates.

- Sheet metal workshop

- Metallic furniture workshop

- Wood furniture workshop.

- Paint workshop

- Laboratory and nondestructive testing.

Repairs

- They are specialists in repairs for the naval sector.

- They carry out nondestructive tests.

- Industrial scaffolding

- They deal with outfitting, boilers, drydock beds, deck equipment, hull treatment, propellers, anodes, grids and sea chests, reapir of life boats, accommodation ladders, and so on.

- They carry out technical test son gas tankers

- Macro x-rays, liquid and global tests.

- Gauging is carried out on all types of vessels.

Military

The military projects are subject to the most demanding regulation on the issue of security and materials. Aspects such as ergonomics and termal and acoustic insulation are essential in projects of this kind.

Gabadi S.L. is a trusted partner, we participate on the idea, we support the engineering, we contribute to the choice of materials, we manufacture to requirements of the projects, and we execute the Project carrying out the total habilitation of the ship.

They have participated in projects for aircraft-carriers, destroyers, submarines, frigates, cargo and supply ships.