M|A|C System Solutions, leaders in collecting performance data from vessel, provide Web-based, Soft and Hardware solutions, assuring continuous development in close cooperation with the customers.

Uniqueadvantage of M|A|C System Solutionsis the modular concept.

It can be gradually built up from simple “off-line” Data Reporting (PMS Reporting) up to Online Data Acquisition (PMS Online) & Performance Monitoring, by installing respective M.A.C Data Collectors.

PMS Reporting consists of a Server (PC/black box) in the ECR, easily installed by the crew and including relevant Software.

Software uploads the data on the “cloud” and gets all updates automatically.

The crew is manually inserting data, as per (existing) Noon Reporting. Relevant Data are automatically sent/uploaded to the Database ashore (“cloud”) and are accessible up to the first day.

On-line System (“PMS Online”) consists of a Server in the ECR (a PC / black box), along with relevant Software which uploads the data on the “cloud” and gets all updates automatically.

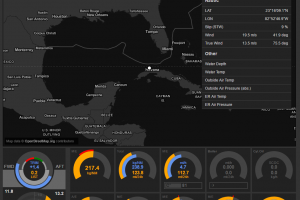

On-line/Real Time Data Acquisition on-board is achieved through M.A.C Data Collectors, such as for:

- Bridge (collecting signals from GPS, speed log, anemometer, water depth, rudder position)

- ECR (collecting Fuel in use, Shaft power meter, rpm), including Inclinometer with interface for ECR Data Collector (Trim/List Sensor)

- ER (Flowmeters) & Temp Sensors

Data Collectors can receive/accommodate all types of signals, while output is always Ethernet.

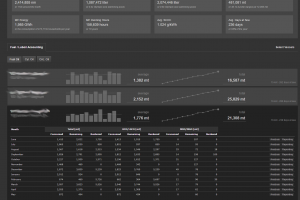

Data are collected automatically & constantly and uploaded to the “cloud”, where they are accessible up to the first day.

In case customers have already their in-house software, then M.A.C can provide only the hardware itself for data collection and transmittance to shore.

Online Electrical Energy Monitoring allows for Collecting shore and auxiliary engines power (SUPPLYcollect), E/R and cargo hold venting consumption (VENTcollect), pumps for circ. oil, ballast water, etc (PUMPcollect)

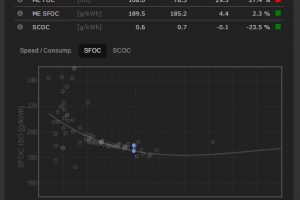

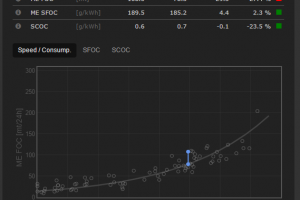

Indicative Major advantages of MAC System is the Web-based Software (since data are automatically uploaded on the “cloud” and accessible with any browser), the useful Visualizations & graphs,

the User-friendly Operation and the modular Setup, keeping installation costs to minimum and allowing integration of all suppliers/consumers onboard.

MRV Regulations

(Monitoring, Reporting and Verification of Carbon Dioxide Emissions (CO2) from maritime transport in Europe)

Vessels larger than 5,000 GT calling EU ports (to, from and between EU ports)

Timeline in detail

- 31 August 2017 – Submission of ship-specific monitoring plans of shipping companies to verifiers for approval

- 1 January 2018 – Start of CO2 monitoring (Data collection) on per-voyage basis

- 30 April 2019 – Preparing, Verifying and then Submitting to EC and Flag State the verified annual CO2 emission report.

- 30 June 2019 – Issuance of DoC and CO2 Emission data made publicly available by the EC

METHODS FOR DETERMINING CO2 EMISSIONS

Actual fuel consumption for each voyage shall be used

and be calculated using one of the following methods:

a) Bunker Fuel Delivery Note (BDN) and periodic stocktakes of fuel tanks;

b) Bunker fuel tank monitoring on board;

c) Flow meters for applicable combustion processes;

d) Direct CO2 emissions measurements.

Verification

Accredited verifiers will have three key tasks:

a. To verify ship-specific monitoring plans (completeness, accuracy, relevance and conformity)

b. To verify that the annual ship-specific emission reports comply with the monitoring plans

c. To verify that the figures contained in the annual ship-specific emission reports are accurate

Emission Factors

Type of Fuel / Emission factors ΙΜΟ values 2012/63(t CO2 / t fuel)

- HFO 3.1144

- LFO 3.1510

- Diesel / MGO 3.2060

- LPG (Propane) 3.0000

- LPG (Butane) 3.0300

- LNG 2.7500

M.A.C System Solutions, experts in on-board Data Acquisition & Performance Monitoring, provide a complete MRV Compliance package, by undertaking the Preparation of the Monitoring Plan & MRV Reporting.